Slaughtering

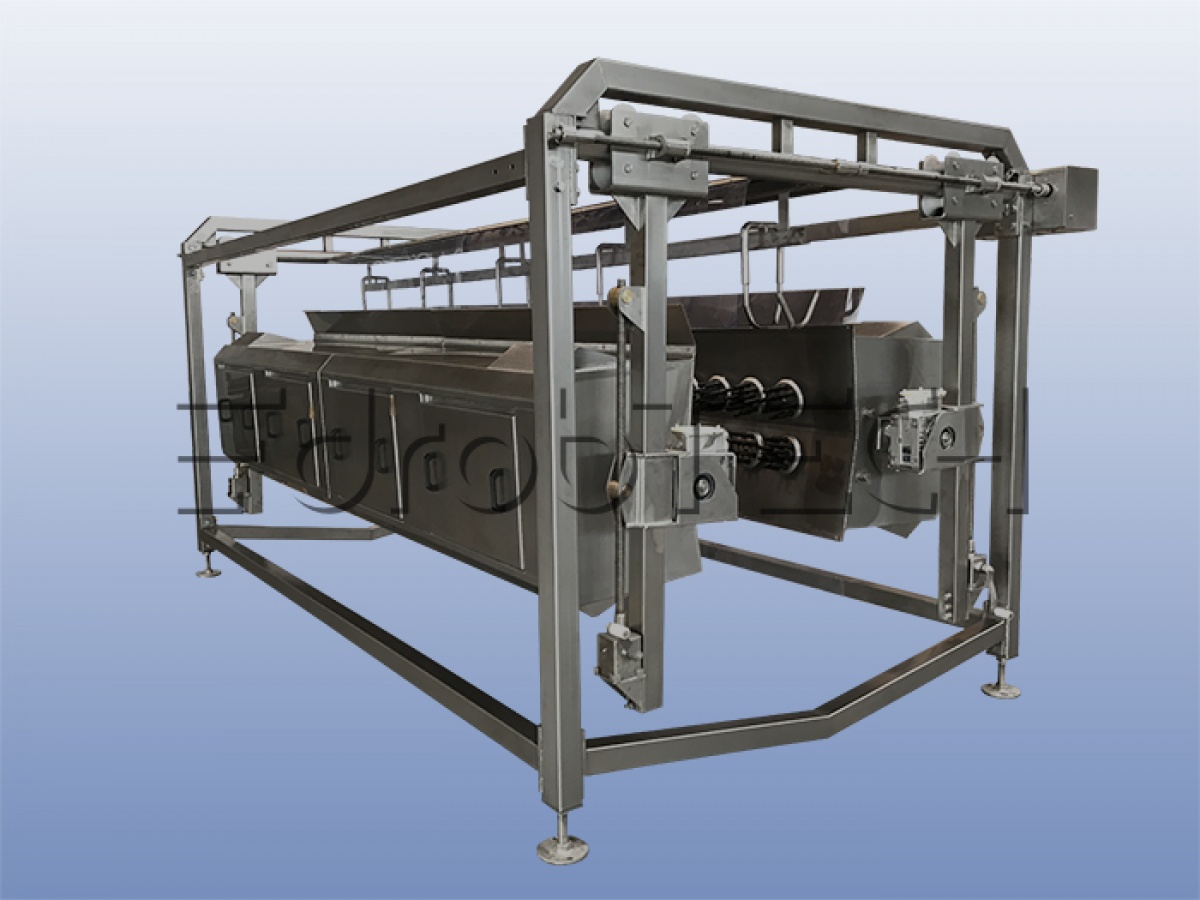

In line plucker 2

The plucker is designed to form part of the killing line. A killing line consists of various machines, each of which plays a part in the killing process. The birds are transported through the machines by means of an overhead conveyor. Each machine operates independently and contributes to the delivery of a clean product, prepared for the evisceration and further processing.

The purpose of the plucker is to remove the feathers from the chickens. When the carcass is heated in an earlier process (hard scalding), the epidermis is also removed from the birds.

Feathers are attached to the skin by means of hair follicles. Soaking the bird in hot water destroys the attachment. This process is referred to as scalding. Following this process, the feathers can be easily removed by rubbing the skin with the hands or with mechanical rubber fingers.

Pluckers are mounted in a plucking line, which consists of different types of pluckers, depending on the capacity of the line and the type of chicken. This ensures an optimum result.

The chickens, hanging vertically by the legs on the shackles of the overhead conveyor, are guided through the pluckers. The pulleys and plucking disks are driven in opposite directions by motors and drive belts. This process, enhanced by the speed at which it occurs, ensures that the feathers are ‘twisted’ out of the birds.

Water pipes are used for the continuous removal of feathers. Loose feathers are kept wet, so that they fall onto the transport belt or into the collecting bin. The wet feathers are pumped away, washed and subjected to further treatment.

The plucker is designed to achieve the following:

- To remove all the feathers from the chicken.

- To remove the skin when scalding is used (hard scalding).

- To ensure that the skin of the bird is not damaged.

- To ensure that no part of the bird is broken or damaged.

The plucker is constructed from stainless steel and synthetic materials. The plucking

disks are manufactured from synthetic material or from stainless steel.

The plucker consists of the following main components:

• Two plucker cabinets.

• Two adjustable legs.

• Eight electric motors.

• Plucking discs.

The plucker is fitted with 32, 40, 64 or 96 rotating disks, each having 12 rubber fingers. The disks

are driven by four electric motors and are positioned such that the shape of the chicken

can be accurately followed. During the plucking process, a water sprayer flushes

the plucked feathers away.

Types:

- US32: 2 x 8 discs per cabinet in total 384 plucking fingers

- US40: 2 x 10 discs per cabinet in total 480 plucking fingers

- US64: 2 x 16 discs per cabinet in total 768 plucking fingers

- US96: 3 x 16 discs per cabinet in total 1152 plucking fingers

Capacity:

- US32 up to 1300 birds per hour

- US40 up to 1800 birds per hour

- US64 up to 2500 birds per hour

- US96 3000 birds per hour

Request more information

Duck processing

Duck processing Quail processing

Quail processing